Metallurgy

Metallurgy is the scientific study of the properties of metals as well as extracting and refining them into useful products. It has been an important part of human civilization for thousands of years and played a critical role in the development of modern industry. History of metallurgy is a fascinating tale of human ingenuity, from the earliest days of metalworking to the cutting-edge technologies of today.

The first proven evidence of attempts at metallurgy dates back to around 5000 BCE, when copper was first used for making tools and ornaments. The discovery of this metal was groundbreaking for humanity, as it allowed us to create more effective and durable tools. The use of copper also heralded the beginning of the Bronze Age, when people saw the development of more sophisticated metalworking techniques. The earliest metal objects from the Bronze Age were still cast from copper, which was extracted from ore deposits in the earth. Copper is relatively soft and malleable, making it easy to hammer or cast into new shapes. However, it all came at a cost. It was not firm enough for warfare applications like weapons or heavy armor – it would bend easily when hit. As a result, this reddish metal was mostly reserved for civilian needs. This is why the discovery of bronze was so significant.

Bronze, a new kind of alloy made by combining copper with tin, was much harder than pure copper while also having better resistance to corrosion. The formula for making bronze was developed during the early Bronze Age, when it is believed that the mixing of copper and tin started. The Bronze Age spanned several thousand years – from around 3000 BCE to 1000 BCE – and saw the rise of many early civilizations, including Egypt, Mesopotamia, and the Indus Valley. These societies were built on the foundation of metallurgy, enabling them to create complex machines, build monumental architecture, even facilitate waging wars against their enemies. Bronze allowed people to reach an unprecedented level of accuracy and sophistication in creating various tools.

The process of making bronze was not as straightforward as ‘heat, mix and stir’. This was an arduous process that took lots of time and patience. The ores were first broken up into small pieces, then roasted in a furnace to drive off impurities. Once the ore had been purified, it was combined with other metals, such as iron or zinc, to create alloys with unique properties. The resulting material was then utilised to create a cast bronze object using the lost-wax technique: making a mould of the object in wax, followed by filling the cavity with molten bronze. Metalworkers had to be proficient in a range of different techniques, including forging, casting, and hammering.

The next major milestone in the history of metallurgy was the discovery of iron smelting, which, interestingly, occurred independently in different parts of the world around 1000 BCE. Iron was much more abundant and easier to work with than copper or bronze, quickly becoming the preferred metal for multiple applications. The Iron Age saw the rise of many new empires and the spread of iron technology across the globe, notably in the Roman Empire, the Han Dynasty in China, the Mauryan Empire in India. During the Middle Ages metallurgy continued to advance, with the development of new approaches for refining gold, silver and other precious metals. The creation of new alloys like brass and pewter also became more common, as did the use of metals in medicine. In the early modern period, metallurgy played a critical role in the development of modern science.

Probably the most impactful point was the invention of the blast furnace. Developed in China around the 3rd century BCE, the blast furnace revolutionized metalworking allowing to produce cast iron on a large scale, kickstarting an even more revolutionary development – the steam engine – which in turn was one of the many breakthroughs that made the Industrial Revolution possible. The Industrial Revolution itself transformed metallurgy into a highly mechanized, even scientific discipline. One particular advance was the Bessemer converter, making mass-production of steel without the need for highly-skilled professionals a reality.

Before the Bessemer process, steel was primarily produced by heating iron ore in a charcoal fire and then hammering it to ensure the material was more uniform. This process, known as wrought iron production, was slow and labour-intensive, with the resulting material ending up not being as strong or durable as modern steel. The Bessemer converter involved blowing air through molten pig iron to burn off undesirable elements as well as to adjust the carbon content, which leads to a higher-quality, more uniform product. This approach was much faster while at the same time being more efficient than previous methods of steel production, and it quickly revolutionized the industry. The so-called Bessemer process was later improved upon with the introduction of new techniques such as the open-hearth process and the basic oxygen process. Today, we produce steel using a variety of methods, but the basic principles of the Bessemer process remain unchanged.

Nowadays, metallurgy is a vast field of study with many different branches and subfields: physical metallurgy, mineral processing, materials science and others. Advancements in production technologies, such as the use of computers, robot-controlled machines as well as automation in general, have made many previously prohibitively expensive things financially viable. Modern alloys are lightweight, strong, and resistant to corrosion – this is just the tip of the iceberg. Metallurgy is a testament to human ingenuity and the power of innovation. From the earliest days of copper smelting to the modern-day production of advanced alloys, metallurgy has been the cornerstone of human civilization. As we continue to push the boundaries of science, metallurgy will no doubt remain an important discipline. It is the tool that ensures we will be able to overcome whatever challenges we might face.

Questions 14-16

Choose the appropriate letters A-C and write them in boxes 14-16 on your answer sheet.

14 Copper was the metal of choice in the early days of metallurgy because of its

A Abundance

B Affordability

C Ease of shaping

15 Military application of copper was limited because the material

A wasn’t strong enough

B found use for more peaceful purposes

C proved to be too bulky

16 One of the advantages bronze has over copper is

A being less prone to rusting

B having tin in it

C its wide use in architecture

Questions 17-21

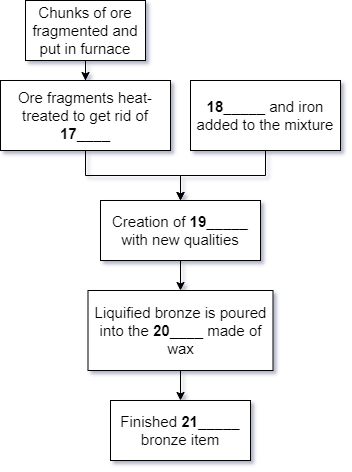

Complete the flow-chart

Choose ONE WORD ONLY from the passage for each answer. Write your answers in boxes 17-21 on your answer sheet.

Questions 22-27

Do the following statements agree with the information given in Reading Passage 2?

For questions 22-27, write

TRUE if the statement agrees with the information

FALSE if the statement contradicts the information

NOT GIVEN if there is no information on this statement

22 Iron smelting was invented in the Roman Empire

23 Blast furnace was one of the biggest breakthroughs of the Industrial Revolution

24 The invention of steel alloy was made possible thanks to the Bessemer converter

25 The Bessemer process made the output material quality more consistent

26 The introduction of machinery in the process of metal making helped reduce production costs

27 It is unlikely that metallurgy will lose its significance in the future

For this task: Answer keys :: Vocabulary